ROBOX technology for your application?

The H2020 project ROBOX aims to widen the industrial application of enzymatic bio-oxidation processes to new and also larger volume and lower price markets. The project has now been running for 2½ years and some successful demonstrations have already been carried out, which means that the consortium is increasingly focussing on the exploitation and replication of ROBOX technology. Following your involvement in ROBOX[1], we would like to share with you in more detail what ROBOX is all about. In particular, we would like to share the type of biocatalyic reactions on which ROBOX technology is applied in order

Why biocatalytic oxidation?

Biocatalytic oxidation can be an attractive alternative to conventional chemical catalysis, because:

- The use of innovative biocatalytic oxidation routes using molecular oxygen (from air) under benign and mild conditions such as ambient temperature, (pH) and pressure can significantly reduce the environmental footprint and improve the economics of processes.

- Biocatalytic oxidations are generally regio-, enantio- and chemo- selective, meaning that the introduction or oxidation of a hydroxyl group occurs only at specific positions of the target molecule in a defined orientation and without affecting oxidation-prone functional groups such as amines or thiols. Such selectivity is unmatched by conventional chemical or chemo-catalytic oxidations and therefore enables novel and shorter sustainable synthesis routes.

- Entirely new molecules are possible through biocatalysis, which cannot be obtained through conventional chemical catalytic processes.

Biocatalytic reactions demonstrated by ROBOX

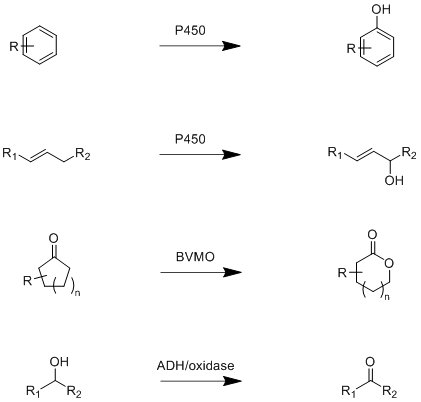

ROBOX focuses on bio-transformations of four types of robust oxidative enzymes:

- P450 monooxygenases (P450s),

- Baeyer-Villiger MonoOxygenase (BVMOs),

- Alcohol DeHydrogenase (ADH)

- Alcohol OXidase (AOX)

ROBOX will demonstrate in total 11 biocatalytic oxidation reactions for target products in pharma, nutrition, fine & specialty chemicals and materials in order to prepare them for scale up to commercial-scale. In order to check for the replicability of ROBOX technology to your processes, we have summarized the essence of the ROBOX reactions in the figure below.

Figure: ROBOX reactions

Want to know more?

If you see opportunities for target molecules or processes of your interest, please leave us your contact details so we can get in touch with you. We will then call your for a first intake to assess the potential and if there is sufficient interest to really assess the potential of ROBOX technology we can bring you in touch with an expert.

|

[1] Through participation in the ROBOX stakeholder analysis, ROBOX dissemination events and on-going collaborations and discussions with ROBOX partners